Precipitated vs Ground Calcium Carbonate: Key Differences, Uses & Benefits

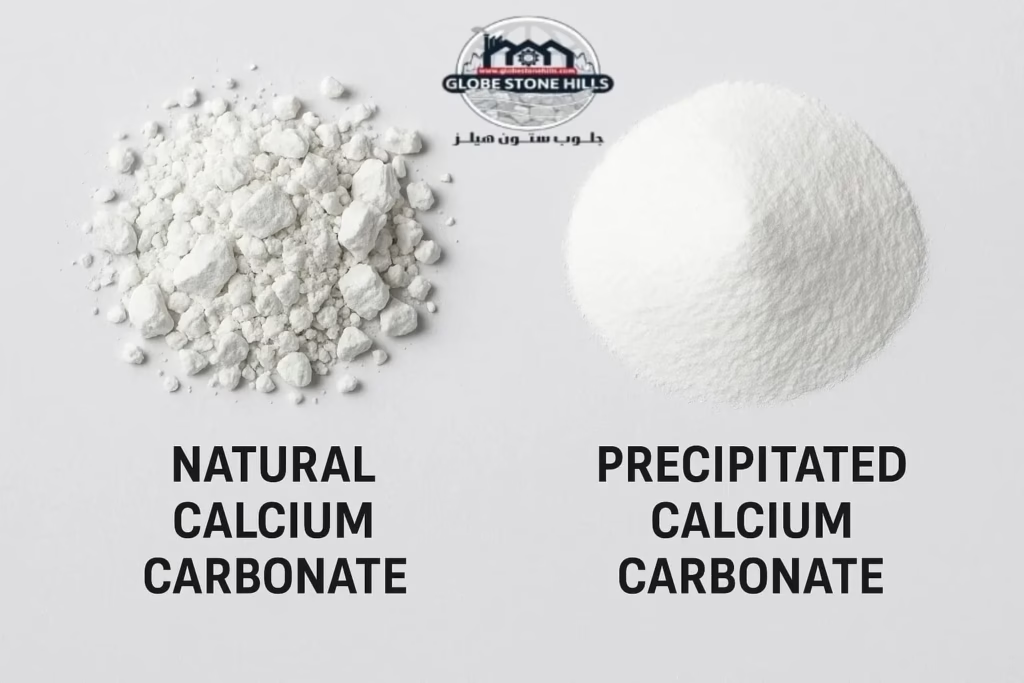

The main difference between Precipitated and Ground Calcium Carbonate lies in their production methods and physical characteristics. While Ground Calcium Carbonate (GCC) is obtained from natural mineral sources like limestone and marble, Precipitated Calcium Carbonate (PCC) is a synthetic form produced through a chemical process. Both forms have unique properties and are widely used in industries such as paints, plastics, paper, and pharmaceuticals.

To learn more about calcium carbonate, click here.

Ground Calcium Carbonate (GCC)

Ground Calcium Carbonate (GCC) is a naturally occurring form of calcium carbonate extracted from limestone, marble, or chalk. It is mechanically ground into a fine powder and used in a wide range of industrial applications.

Production:

GCC is obtained by mechanically crushing and grinding natural mineral sources.

Chemical Composition:

CaCO₃ (Calcium Carbonate)

Key Properties of Ground Calcium Carbonate:

High Purity: Suitable for many industrial uses.

Chemical Stability: Stable under most processing conditions.

Dispersibility: Easily mixes into paints, polymers, and coatings.

Whitening Effect: Commonly used to enhance whiteness in calcium carbonate in paper applications.

Common Uses of Ground Calcium Carbonate:

Paints: Used as a cost-effective filler to improve opacity and brightness.

Plastics: Enhances rigidity and reduces raw material cost.

Food Industry: Used as an additive in food products and animal feed.

Pharmaceuticals: Serves as a calcium supplement and tablet excipient.

Cosmetics: Acts as a filler and bulking agent.

Paper Manufacturing: Improves whiteness and smoothness.

Precipitated Calcium Carbonate (PCC)

Precipitated Calcium Carbonate (PCC) is a refined, synthetic version of CaCO₃ created through a controlled chemical reaction, resulting in a more uniform particle structure and higher purity.

Production:

PCC is synthesized by reacting calcium hydroxide (obtained from quicklime) with carbon dioxide to precipitate synthetic calcium carbonate.

Chemical Composition:

CaCO₃ (Calcium Carbonate)

Key Properties of Precipitated Calcium Carbonate:

Fine Particle Size: Enables high surface area and smoothness.

Controlled Crystal Structure: Provides consistency in product performance.

High Brightness: Ideal for coatings and paper fillers.

Enhanced Compatibility: Performs better in plastics and rubber applications.

Common Uses of PCC:

Paper Industry: Improves brightness, opacity, and printability.

Paints & Coatings: Enhances coverage and wear resistance.

Plastics: Improves flexibility, hardness, and gloss.

Rubber: Increases elasticity and mechanical strength.

Food & Pharma: Used as a calcium carbonate supplement and food additive.

Construction Materials: Acts as a functional filler in adhesives and sealants.

While both Precipitated and Ground Calcium Carbonate share the same chemical formula, their differences in particle size, structure, and purity affect their performance and applications. Ground Calcium Carbonate is widely used for general applications, while Precipitated Calcium Carbonate is preferred for high-performance needs requiring consistent quality and enhanced properties. Understanding these differences is essential for selecting the right material in industries such as plastics, paints, pharmaceuticals, and paper manufacturing.

About the largest company in grinding and producing calcium carbonate Globe Stone Hills

Recent Posts

- Globe Stone Hills: Your Comprehensive Guide to High-Quality Calcium Carbonate Solutions

- The Role of Calcium Carbonate in Soap and Detergent Manufacturing

- Precipitated vs Ground Calcium Carbonate: Key Differences, Uses & Benefits

- Calcium Carbonate Quarries in Egypt | High-Purity White Mineral for Industries

- Difference Between Coated and Uncoated Calcium Carbonate

Latest Posts

Contact the Globe Stone Hills team

Gallery

- © Copyright 2024. Globe Stone Hills